One Group. Concretely safe.

Safety in the workplace is a fundamental value of Cementir's culture of sustainability, as is the protection of the health of employees.

Occupational Health and Safety Policy

We firmly believe that the framework for prevention of work-related incidents and illnesses is the effective implementation and maintenance of OH&S management system aligned with international reference standards and our guidelines and rules. Our commitment is based on the following key requirements.

- Set clear goal and targets and specific action plans with a systemic approach. H&S is an integral part of our strategy.

- Establish clear accountabilities and responsibilities. Respect procedures and rules by workers to guarantee health and safety of all. H&S is a line responsibility. Everybody has a role and responsibility to prevent incidents.

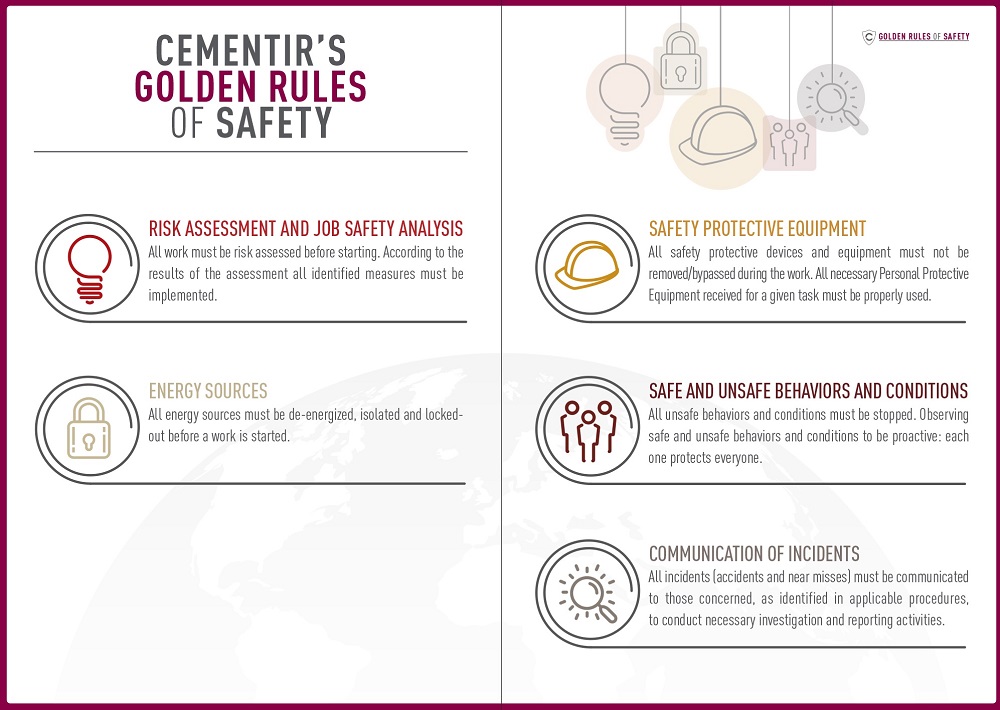

- Identify and assess the hazards and risks associated with all operational activities (e.g. routine and non-routine, complex operations) as a precondition to provide safe and healthy workplace. H&S is about conducting a prior risk assessment for any operation.

- Define work-related procedures and practices and up to date them considering the risk assessment, regularly reviewed. Putting in place proven reliable barriers and controls to mitigate risks. H&S is an integral part of all activities, daily.

- Train and coach employees prior to start their work-related activities. Implement and develop awareness and competence to fulfil their tasks safely. H&S culture is an attitude that need to be trained and encouraged.

- Learn from accidents and near misses and share experiences with employees. Investigate and report the root causes rigorously. H&S is to learn from failures as well as successes.

- Comply with all applicable local, regional, national and international Health, Safety and Environment legislation as well as corporate guidelines and rules. Review regularly workplaces and tasks to ensure the compliance. H&S compliance is mandatory and must be constantly guaranteed at all levels of responsibility.

- Monitor, audit and review regularly the adequacy and effectiveness of OH&S management system, procedures and performances according to reference indicators and Group guideline. Define and implement any necessary corrective measures. H&S is to focus on continuous improvement.

- Develop a relationship of constructive cooperation, based on utmost openness and trust, both within the group itself and vis-à-vis the external community and the Institutions in the management of health and safety topics. H&S is to promote transparency and collaboration.

The Occupational Health and Safety Policy is approved by the Group CEO and by the Group COO and applies to all operations of the company, covering all employees, contractors, and other individuals working on behalf of Cementir Group (such as contractors, suppliers, and consultants).

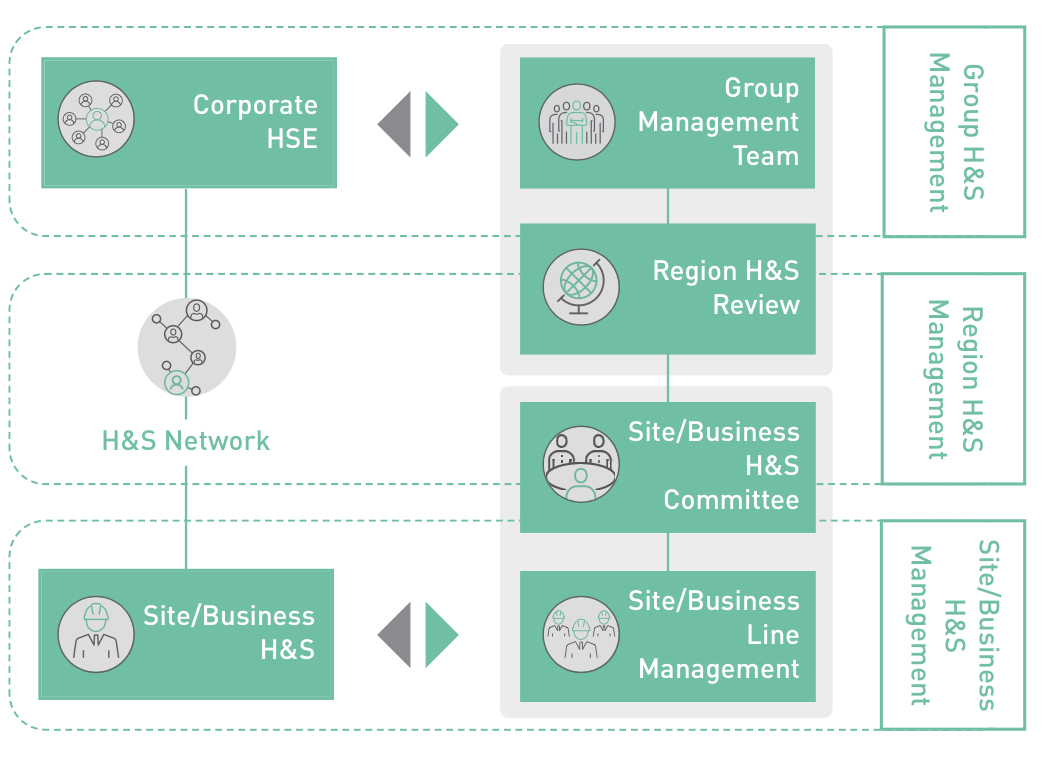

A strong H&S governance

The global interconnected Health and Safety Network, coordinated by the Corporate HSE Function as technical area, supports all organizations to share competences, good practices and initiatives. The Network consists of all managers/coordinators on Health & Safety at site/business level which support the line management technically in the implementation of management system locally (e.g., risk factors identification and assessment, safety operating procedures, operational standards and controls, incident investigations, inspections, etc.). The Network deliverables are constantly distributed to all workers through local Health & Safety (e.g., safety alerts, common rules and standards, etc.).

Specific health and safety targets are considered in short-term remuneration for representatives and managers based on risk level of the different business.

Our Health and Safety Management System

Our framework for prevention of work-related incidents and illnesses is the effective implementation and maintenance of the Health and Safety Management System according to the ISO 45001 standard, the Group guidelines and standards and the regulation in the countries where we operate.

The Management Systems Certification Program has been completed in 2023.

We strongly believe that the goal we achieved leads to the harmonization of preventive practices through the entire Group and is aimed to improve management and safety performance.

Where we are

In 2024:

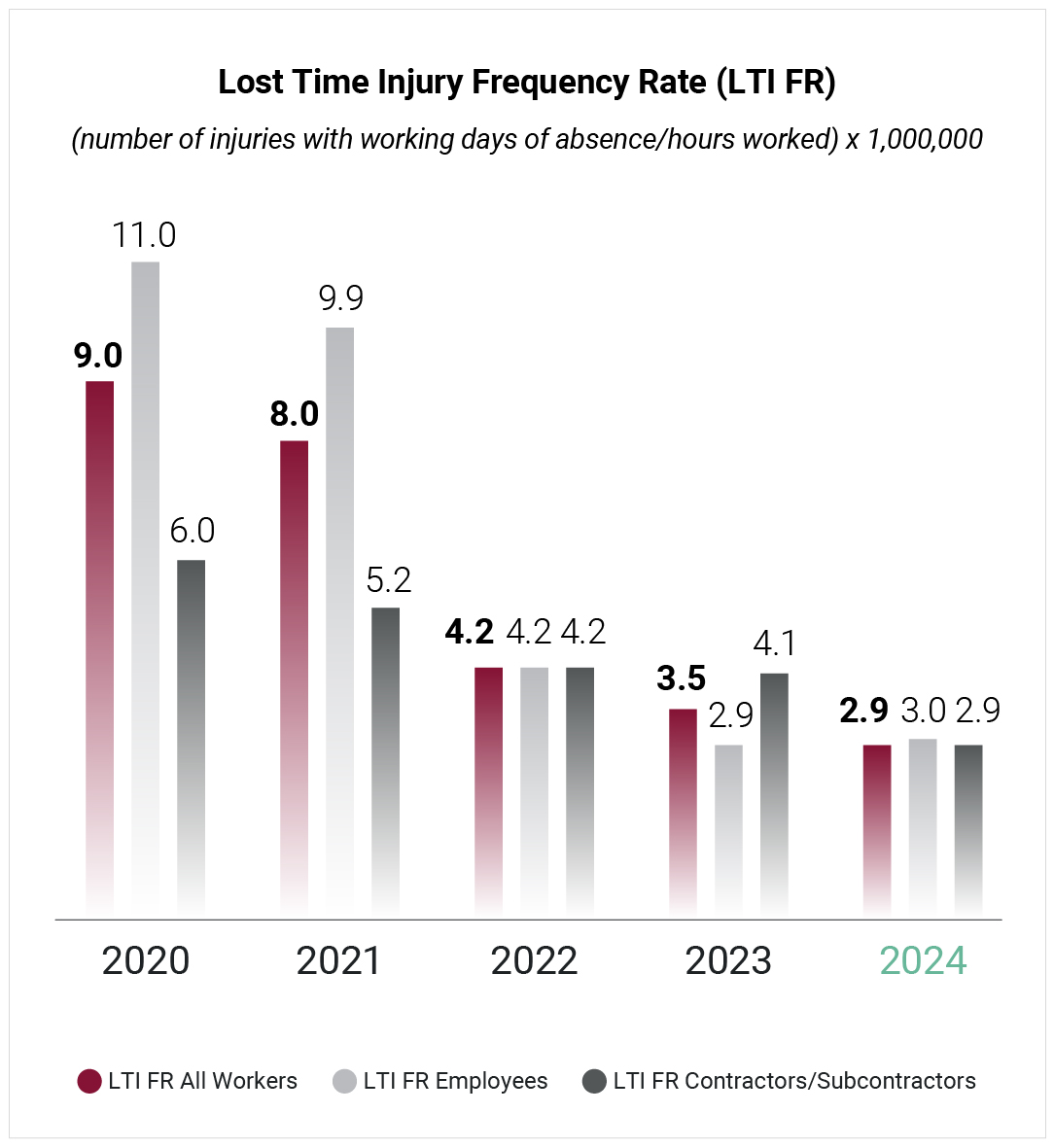

- The total number of lost time injuries has been reduced by 16% compared to 2023.

- The main causes of incidents were slips, trips and falls (about 30% of the total) mostly concerning behaviours. Specific initiatives were undertaken during the year to increase the level of worker awareness and supervision and control activities in the field.

- 58% of people in our own workforce are covered by the Health and Safety Management System certified ISO 45001.

- H&S specific training was 30,911 hours aligned with the previous year considering also that some activities are carried out periodically. It has to be noted that H&S training hours represent more than 40% of the total Group training hours.

- During the year, no occupational illness allegations were received.

Watch the video dedicated to "One Group"

Our key leading activities

Our roadmap to strengthen safety culture is based on six pillars of action where interdependent approaches by workers is a key expectation.

To be effective in the implementation of our “Zero accident strategy” the main attitude required, starting with our managers, is leadership to be felt through visible and exemplary behaviors, proactive commitment and indeed the involvement of workers viewed as a team.

-

Leadership in Practice

- Managers Safety Walk&Talk program focused on behaviors

- Participation in incident investigations

- Training program on “Concrete Leadership”

- Safety Leading Targets

-

Commitment & Responsibility

- Interdependent approach to safety starting from induction phase

- Proactive contribution of all workers

- Positive reinforcement (e.g., Safety Valuable Behavior)

- Procedures effectiveness and discipline in practice

-

Risk Management

- Identify hazards in all conditions

- No work prior to proper risk assessment and authorization

- Training program on “Job Safety Assessment”

- Timely implementation of preventive and corrective actions that are identified

-

Involvement & Participation

- Regular Committees and operational meetings

- Periodic toolboxes at department/shift level on the main risk factors

- Participation in the preparation of safety operating procedures

- Participation in incident investigations and results dissemination (e.g., Safety Alert)

-

Competence & Awareness

- Safety training on both technical skills and personal attitudes

- Training matrix including all workers and jobs

- Periodic campaigns on incident communication and reporting of unsafe behaviors and conditions

- Safety attitude as evaluation factor on individual performance

-

Continuous Improvement

- Learning from events through Root Cause Analysis

- Systemic implementation and reviewing of standards and best practices

- Monitoring of both lagging and leading KPIs and auditing (including contractors)

- Valuable Safety Behaviors

As every year, the Group celebrated the World Day for Safety and Health at Work an important opportunity to reaffirm our ongoing commitment to ensuring safe and healthy working environments for everyone.

Our goal is to influence the safety attitudes of our truck drivers, involving and training them in risk identification, rules, practices, and behaviours to follow for safe driving.

We launched a strategic project with the aim to implement a unique Group platform cloud-based to manage key H&S processes, including mobile App, for all company/business/plant.